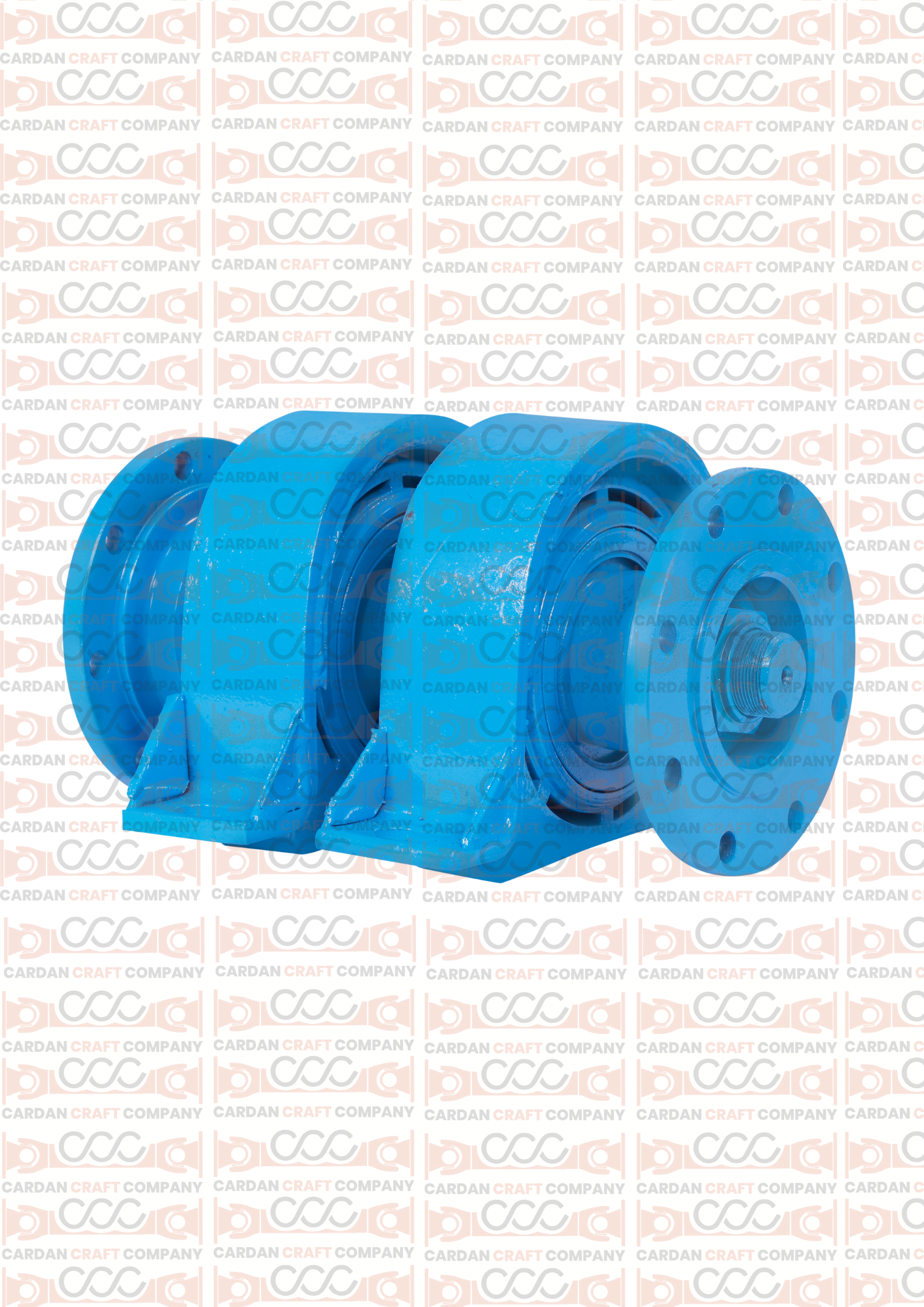

Cardan Shafts For Mining Application

CCC

₹1500.00

Cardan Shaft for Mining Applications: Engineered by Cardan Craft Company

Mining is not just an industry—it's a test of endurance, reliability, and raw strength. At Cardan Craft Company, we understand the extreme demands mining operations place on every component of machinery. That’s why we offer Cardan Shafts specifically engineered for mining equipment—where performance, durability, and precision aren't optional; they are essential.

Our Cardan Shafts are built to endure harsh underground environments, high torque loads, and variable misalignments. They play a vital role in transferring rotational power between shafts that are not in a straight line, especially in dynamic applications such as crushers, loaders, conveyors, and drilling rigs used in mining operations.

What Makes Our Cardan Shafts Mining-Ready?

1. High Torque Capacity

Mining applications often involve extreme torque requirements. Our shafts are designed using premium alloy steels such as EN-8, EN-19, and EN-24 to withstand immense torsional stress. Each shaft is optimized for your machine’s torque needs and tested under load to ensure reliability in real-time conditions.

2. Custom Engineered for Your Machines

No two mining machines are identical. Whether you need longer shafts, specific spline configurations, or unique flange designs, we offer completely customizable solutions. Simply share your technical drawings or discuss your application with our engineers, and we’ll develop the right fit.

3. Advanced Machining and Balancing

Precision matters, especially in continuous operations. Our shafts are CNC-machined to achieve tight tolerances, ensuring smooth rotation. We also dynamically balance each shaft to eliminate vibration, reduce wear, and ensure operator safety.

4. Built for Harsh Environments

Dust, moisture, vibration, and heat—our shafts are designed to resist them all. Special coatings such as zinc plating, black oxide, or industrial paint are used to prevent corrosion. Grease points and sealed UJs further ensure long service intervals.

5. High Flexibility Joints

Mining machinery is often exposed to movement and angular misalignment. Our Cardan Shafts feature Single and Double Universal Joint options to provide flexibility without sacrificing torque transfer.

Key Technical Specifications

Material: EN-8 / EN-19 / EN-24 (as per application requirement)

Tube Profile: Round, Seamless Heavy-Duty Pipes

Length: Custom as per machine layout

Joint Type: Single/Double UJ with options for Slip Yokes and Spline Ends

Balancing: 100% Dynamically Balanced

Surface Coating: Black Oxide / Zinc Plated / Painted

Lubrication: Grease Nipples Provided for Maintenance

Application Fitment: Suitable for most Indian and imported mining equipment brands

Applications in Mining Sector

Our Cardan Shafts are trusted by operators and OEMs across a wide range of mining equipment:

Crushing Units (Jaw Crushers, Cone Crushers)

Earthmoving Loaders & Dumpers

Conveyor Belt Systems

Tunnel Boring Machines

Stone Crushers & Screens

Hydraulic Excavators & Rock Drills

Drilling and Blasting Machines

Longwall and Continuous Miners

Every shaft is designed with real working conditions in mind, tested under simulated loads, and backed by Cardan Craft’s service guarantee.

Why Choose Cardan Craft Company?

Heritage Meets Modern Engineering

With decades of experience in precision shaft manufacturing, we combine traditional craftsmanship with state-of-the-art technology. Our in-house engineering team collaborates with clients from concept to completion.

Zero Compromise on Quality

From sourcing raw materials to post-production inspections, we follow rigorous quality control measures. Each batch is tested for strength, alignment, hardness, and dynamic balance.

Client-Centric Approach

We believe in long-term partnerships. From helping you choose the right shaft configuration to supporting you with spares, modifications, and replacements, our support doesn’t end with delivery.

Ready-to-Dispatch Inventory + Custom Jobs

We maintain a ready stock of commonly used shafts and can also take up urgent custom jobs, reducing downtime for our clients.

Reliable Lead Times

Thanks to our streamlined production, we offer quick turnaround without compromising quality.

Let’s Build Strength Together

When your equipment is deep inside a mine, failure is not an option. A single shaft failure can halt an entire operation. That’s why our focus is not just on building products—it’s on delivering assurance.

At Cardan Craft Company, we’re committed to delivering mining-grade Cardan shafts that match the strength of your machines and the ambition of your business.

Contact Us Today

Let's discuss your technical needs and help you get the right solution for your mining application. Whether you're an OEM, distributor, or direct user, Cardan Craft is here to deliver strength, rotation, and reliability.

Connect

Your trusted partner in industrial machinery solutions.

Quality

Support

cardancraftcompany@gmail.com

+91 87009 19393

© 2025. All rights reserved.